Shotcrete / Concrete Restoration

Shotcrete has often been described not as a material but as a process. Both wet and dry processes produce a material that exhibits superior hardened properties to high quality conventional concrete, such as high strength, low permeability and high durability. These properties allow shotcrete to be used in most cases as a structural material. Although the hardened properties of shotcrete are similar to conventional cast-in-place concrete, the nature of the shotcrete placement process provides additional benefits, such as excellent bond with most substrates and instant or rapid capabilities, particularly on complex forms or shapes.

Shotcrete:

- Is flexible and easy to install:

- Uses space more efficiently by allowing, vertical excavation of alternate panels, creating stable vertical walls very close to other buildings:

- Saves money-can concrete right over the shotcrete (one side forms only): and

- Can be more economical than other systems because of the ability to build maximum dimensions of the property and use the excavation as the form system.

Process Benefits

- Little or no form work is required:

- Cost effective method for placing concrete:

- Ideal for irregular surface applications: and

- Allows for easier material handling in areas with difficult access.

- Restores structural integrity to concrete and masonry structures

- Provides permanent seal against corrosion, infiltration, exfiltration

- May be applied by hand-held or remote-controlled spray equipment

- 10- to 50-year design life, dependent upon product and application

- Products are factory pre-blended to assure quality and performance

- Allows monolithic coatings of 1/2 to 8 inches thick

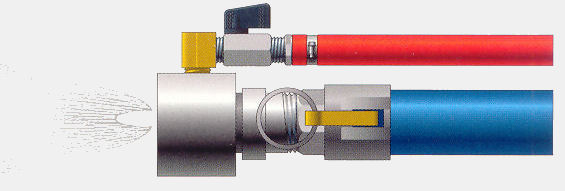

Innovative Solutions for the Trenchless Rehabilitation

and Replacement of Pipelines and Other Structures

and Replacement of Pipelines and Other Structures